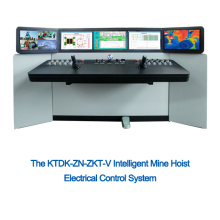

Intelligent Mine Hoist Electrical Control System

| Unit Price: | 100000 USD |

|---|---|

| Min. Order: | 1 Set/Sets |

| Packaging: | wooden case for export |

|---|---|

| Productivity: | 100/month |

| Brand: | huafei |

| Transportation: | Ocean,Land,Air,by train |

| Place of Origin: | china |

| Supply Ability: | taylor make |

| Certificate: | ce/iso9000 MA |

| Port: | Shanghai,Qingdao,Ningbo |

Basic Info

Model No.: The KTDK-ZN-ZKT-V

Click on the follow link to find out more information: https://www.intelligentmine.com/winch-hoist-control/

Company Info

- Company Name: Jiaozuo Huafei Electronic & Electric Co., Ltd. ZhongKuang (Hainan) Technology Co., Ltd.

- Representative: Zhao hui

- Product/Service: Medium Voltage VFD , Explosion Proof VFD , Intelligent Mine , Hoist Electric Control , Belt Conveyor Electric Control , Automation Control System

- Capital (Million US $): RMB20,000,000

- Year Established: 1996

- Total Annual Sales Volume (Million US $): US$50 Million - US$100 Million

- Export Percentage: 41% - 50%

- Total Annual Purchase Volume (Million US $): US$10 Million - US$50 Million

- No. of Production Lines: 5

- No. of R&D Staff: 71 -80 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 50,000-100,000 square meters

- Factory Location: No.1908 Yingbin road High-tech district Jiaozuo City Henan Province China

- Contact Person: Mr. Ginger

- Tel: +86-391-3567086

Premium Related Products

Other Products

Hot Products

H Type Broiler Poultry Cage EquipmentSilo EquipmentPlastic Chicken Transport CagePlastic Chicken Floor Mesh19712 Eggs Chicken IncubatorChicken Manure Clean MachineAutomatic Pullet Chicken Cage of a Frame with Certificate of ISO9001Galvanized Pullet Chicken CageHeavy Hammer Type Exhaust FanAutomatic H Type Broiler CageHot Sale Galvanized Chicken Cage Certificate ISO9001Poultry Layer House A3l90High Quality Automatic Drinking SystemAutomatic Poultry Cage for BroilerAutomatic H Style Battery Layer CageHigh Quality A Style of Layer Cage